Industry news

What is the key to the control of nickel and cobalt during the operation of the intermediate frequency electric furnace?

Release date:2019-04-26

Nickel and cobalt are elements of similar physicochemical properties. Due to the low-simple and simple handling of alloying elements, the key to control is as follows.

(1) Prevent the formation of nickel, cobalt and low melting point sulfides

When exercising varieties with high nickel and cobalt content, the sulphur content of the ingredients is low, and the Mn:S ratio is high, preventing the low-melting sulfides in the steel from lowering the thermoplasticity of the steel.

(2) Manipulating the hydrogen content of molten steel

When using electrolytic nickel, high temperature annealing should be performed to reduce the hydrogen content and reduce the amount of hydrogen introduced into the molten steel.

(3) Saving resources and reducing costs

Nickel and cobalt are important scarce resources. When formulating, they should be accurately calculated. Under the premise of not affecting the performance of the process and drinking performance, it should be compounded according to the middle and lower limits.

(4) Participation and recovery rate of nickel and cobalt

Nickel and cobalt are all used in pure metal. Usually, they are loaded into the crucible with the charge. When participating in a small amount, they participate in the molten steel during the refining period.

Nickel and cobalt are chemically stable elements, the recovery rate of exercise is 98%~100%, and the returning material is 94%~98% when exercising.

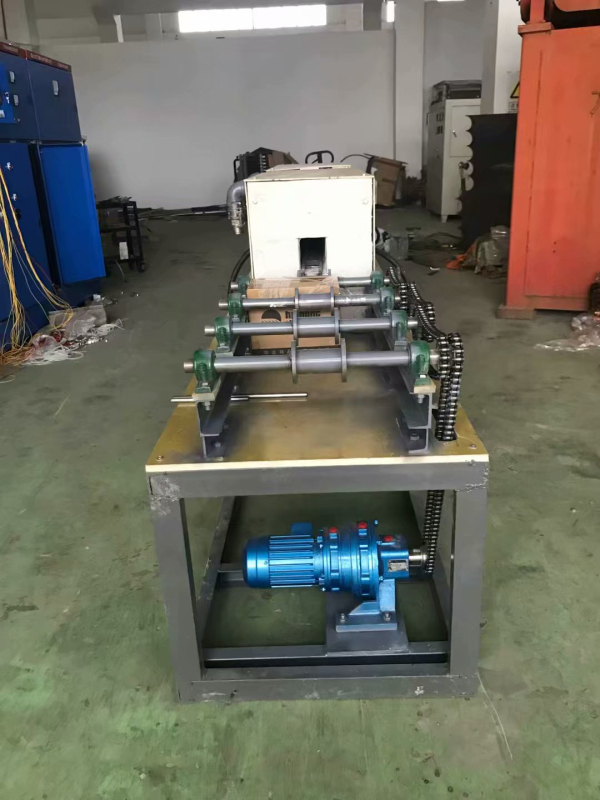

For more information about the intermediate frequency electric furnace, diathermy furnace and induction furnace of Kunshan Wantai Electric Furnace Co., Ltd., please contact Xiaobian.

Medium frequency electric furnace, diathermic furnace, induction furnace,